Implants

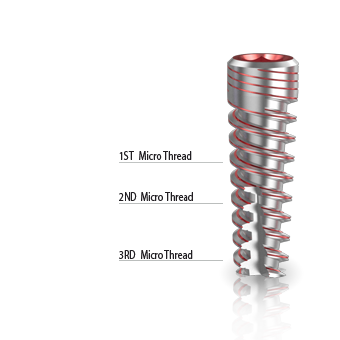

BIO CLEAR IMPLANT

This dental implant is a concept based on Spiral Implant. The Conical structure of the implant, single-threaded

and self-drilling head of the implant is identical to the Spiral Implant.

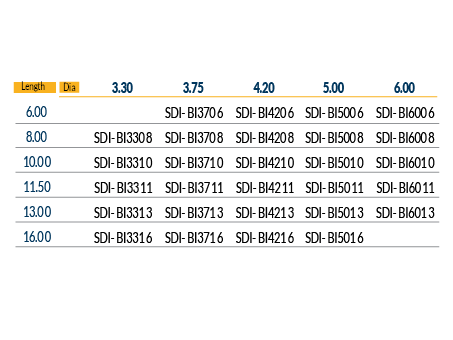

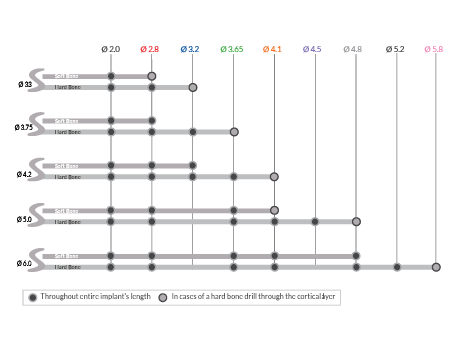

Drilling Information

The recommendations presented in this drilling Protocol, based on long experience of specialists in the world.

However it is important to examine each case on its merits based on the physician’s ability to perform the procedure,

and the state of the patient’s jaw implant transpires with the beginning and there may be changes according to the situation.

In principle, we recommend using a drill that its diameter smaller than the diameter of the implant, in the case of soft

bone condition. Also, consider using a similar drill diameter implant intended for implantation in the case of hard bone

in order to avoid trauma to the bone and ensure rapid bone building around the implant.

Innovation

To encourage bone growth around this unique implant and creating Osseo integration, the company developed with Ghimas

S.p.A a unique gel, SLURRY in a physical form that is characterized by a micro dispersion of solids in a gel. This gel has an

ultra microstructure of the solid which, being in a sufficient amount of liquid, cannot settle, with complex physical interactions

between the solid particles surrounded by hydrophilic molecules and forces of chemical attraction thus keeping the product

fluid and cohesive.

From a biological standpoint the SLURRY ensures better Bio-compatibility and more harmonious degradation of the polymer

and copolymer and of theco-formulates, which are therefore more easily absorbed by the organism using normal metabolic

systems (e.g. the KrebS CyclE).

The unique combination of pure titanium implant with mechanical roughening (without and chemical substances that cause

infection) combined with our Unique gel is to our experience one of the best implant solutions available in the market.

Proven clinical experience of using these implants in recent years testifies to the success and consistency of the proposed

process benefits.

The first generation of osseointegrated implants had a relatively smooth machined surface (Branemark et al.

1969). The machined surface was the first used surface in clinical dental applications and has excellent long time

follow-up (Adell et al., 1981; Br’nemark et al.,1977).

It is well known that smooth surfaces like glass promote fluid movement as opposed to rough surfaces, thus a

constant flow of liquid around the implant at bone contact is essential and a promoting factor to ossesiointegration.

After years of research that included world known practitioners and researchers from well known medical

institutions, We decided to enhance the remarkable success of the DYNAMIC implant and to produce a series of

implants which are based on computerized mechanical corrugation. The computerized mechanical corrugation

increases the surface of the implant and creates a morphology that exhibits excellent conditions for integration

between the implant to the bone. The uniqueness if this process is that the implant surface conditions are

produced during the machining process using specially developed blades for this purpose.