Implants

CYLINDRICAL IMPLANT

The excellent solution for very hard bone or cases of limited vertical bone volume.

The Cylindrical is a standard cylindrical implant with a unique body and core

design that provides minimal pressure on hard bone, and therefore, most suitable

for use with bone types I and II.

Anodized coating technology unique anti-bacterial process

• The implants undergo an anodized coating process which contributes to the creation of an anti-bacterial shell on the

Titanium.

• The coating is made from natural ingredients Food Standard \ Medicine and unattended polluting industrial materials.

• The anodizing contributes to the mechanical strength and prevents friction between the Implant and prosthetic parts.

• Surface treatment unique approach

• Our company has adopted the method of surface treatment based on SLA or the RBM technology using quality materials

to create desired implant Topography. We have chosen not to use chemicals and industrial pollutants which may be

harmful. We decided to use citric acid naturally stabilized as a key component in the process of removing residue media

during surface treatment.

• The use of natural acid ensures very good implant bone contact and prevents situations of rejection of implants resulting

from acid treatment consisting of aggressive industrial chemicals that are decomposed after a certain period.

• This process is unique and is based on years of experience and f thousands of implants manufactured and implanted

around the world.

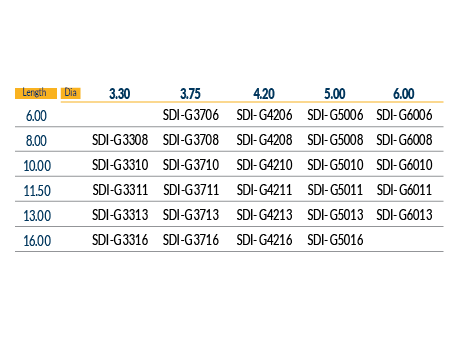

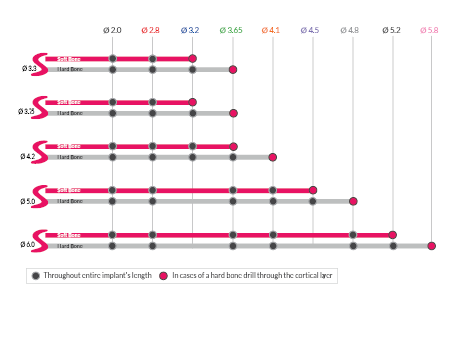

Drilling protocol

The recommendations presented in this drilling Protocol, based on long experience of specialists in the world.

However it is important to examine each case on its merits based on the physician’s ability to perform the procedure,

and the state of the patient’s jaw implant transpires with the beginning and there may be changes according to the

situation.

In principle, we recommend using a drill that its diameter smaller than the diameter of the implant, in the case of soft

bone condition. Also, consider using a similar drill diameter implant intended for implantation in the case of hard

bone in order to avoid trauma to the bone and ensure rapid bone building around the implant.