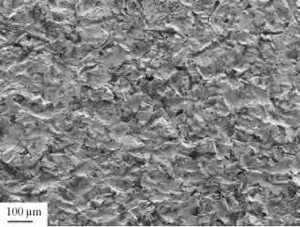

SDI's sandblasted surface

Increased roughness of an implant could be achieved by blasting the surface by small Particles, usually called sandblasting or grit blasting. When the particles hit the Implant surface it will create a crater.

The surface roughness is hence dependent on the bulk Material, the particle material, the particle size, the particle shape, the particle speed and the Density of particles .

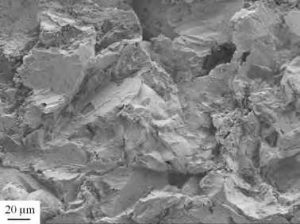

The resulting surface roughness is usually anisotropic consisting of Craters and ridges and occasionally particles embedded in the surface. The surface roughness increases with the size of the particles used Where 25 μm particles blasted surfaces were rougher than the machined surface while Smoother than 75 μm and 250 μm blasted surfaces.

Typical Sa values are 0.5-2.0 μm. Further, implants blasted with 25 μm and 75 μm particles show higher removal torque compared to a machined implant surface after 12 weeks of healing in either rabbit tibia or femur.

Significantly higher bone-implant contact was observed for the 25 μm blasted surface Compared to machined surface while the bone area within the threads were significantly Higher for the machined surface after 12 week and 1 year healing. The blasting particle material, either TiO2 or Al2O3 with a size of 25 μm, didn’t show any difference in bone response with respect to removal torque, bone implant Contact and bone area after 12 weeks healing. Similar Removal torque while significantly higher bone-implant contact and bone area was observed for implants blasted with 25 μm particles compared to 250 μm particles.

The biological response to blasted implants show an optimal bone response with Regards to removal torque values and bone implant contact to implants when a roughness of 1.5 μm is achieved. No ultrastructural studies of the interface between Bone and implant surface have been found in the literature for blasted implants .